Applications

Automotive Industry

Mrodin’s laser technology is ideal for automobiles, commercial vehicles, motorcycles, railway vehicles, bicycles, and agricultural and forestry machinery. It provides traceability and protection against counterfeiting through permanent, precise markings that meet quality standards at levels 1, 2, and 3.

Mrodin’s laser machines enable processes such as structuring, cutting, drilling, stripping, and cleaning, among others, often in compliance with legal requirements. These solutions are adapted to the needs of large manufacturers, integrators, and suppliers in the automotive industry, as well as to small-scale production, individual items, and customization and maintenance projects for railway vehicles, caravans, and tunnels.

Marking Solutions for Chassis Components

Mrodin’s laser marking technology provides reliable traceability for critical chassis components. By engraving unique codes and specific data, manufacturers can ensure structural integrity and comply with the automotive industry’s strict safety standards. In addition, the precision and speed of the laser process streamline production without compromising the quality or durability of the parts.

Laser Marking of Electronic Components

Vehicle Customization with Laser Technology

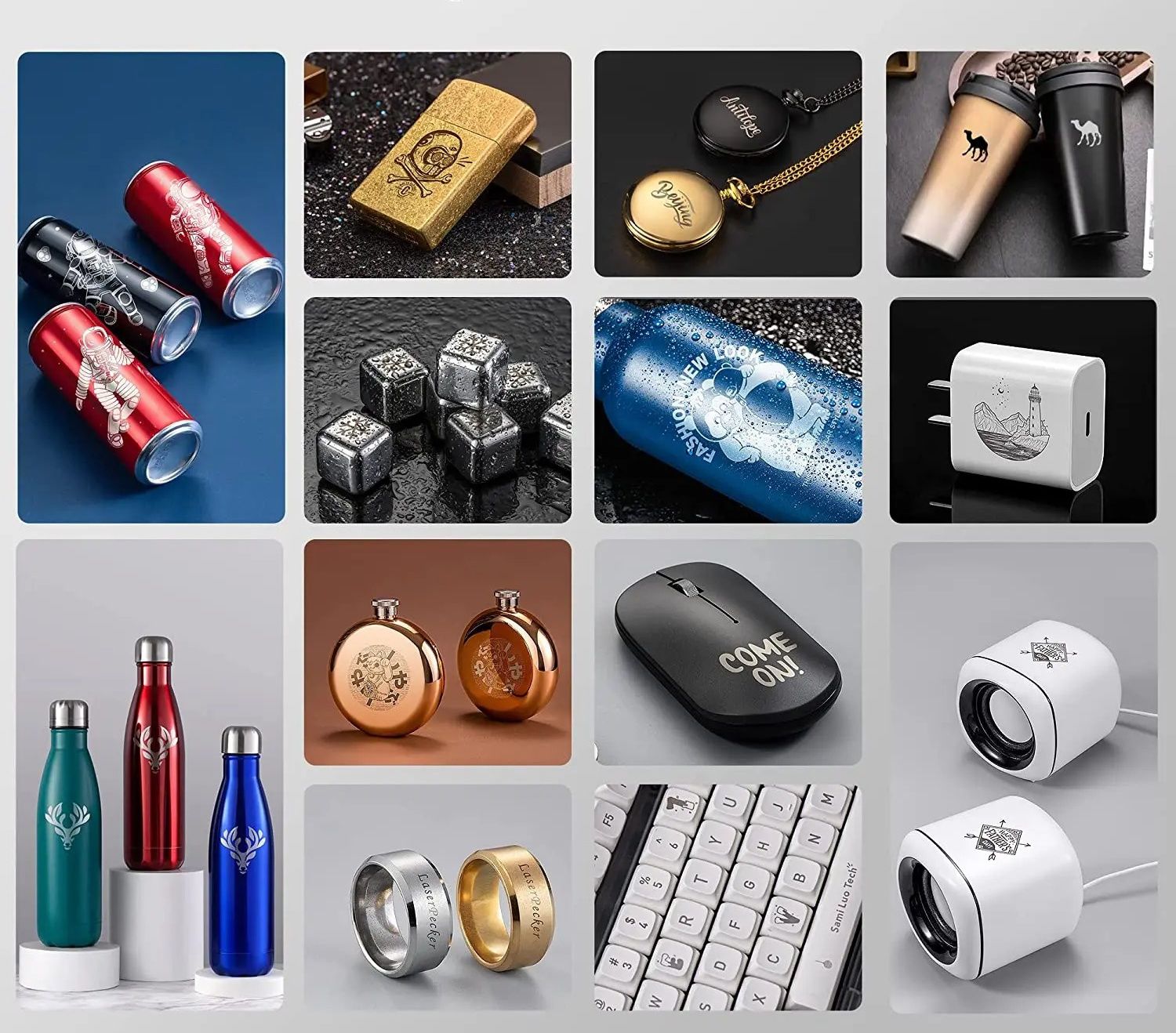

Mrodin Laser Engraving

Precision and Versatility in Production

Laser engraving machines have become an essential tool for creating high-quality customized products. Thanks to their precision and versatility, it is possible to engrave logos, names, and unique designs on a wide variety of materials such as metal, glass, leather, or wood. In addition, the laser process does not damage the original surface, ensuring flawless and durable finishes. These advantages make laser engravers ideal for both craft and design businesses, as well as large companies looking to differentiate their products through customization.

Interior and Exterior Signage

Advertising and Signage

Electronics Sector

Architecture and Construction

Laser Marking of Machining Tools

Product Traceability Throughout the Lifecycle.

Preventing Part Mix-ups in the Production Process.

Flexible, Permanent Customization Even for Small Batches.

The Laser Revolutionizes Creative Crafts.

The use of laser technology in the creative sector represents a paradigm shift, radically transforming the approach to craftsmanship. This innovation enables exceptional levels of precision in designs and cuts, translating into added value and the optimization of production processes. Laser technology empowers artisans to create intricate patterns and high-quality custom pieces, thereby strengthening competitive differentiation in the marketplace.

By working with a wide variety of materials – from wood and leather to glass and metal – the implementation of laser technology is positioned as a strategic solution that drives operational efficiency and accelerates production turnaround times. This synergy between technological precision and artisanal creativity not only reinforces innovation but also contributes to sustainability and enhances brand value in an increasingly demanding business environment.

Artistic Engraving on Wood

- Creation of complex details, ornamental patterns, and reliefs.

- Customization of decorative objects, furniture, and gift items.

Customization on Leather and Textile.

- Engraving of logos, names, or illustrations on wallets, handbags, and garments.

- Precise finishes on artisanal fashion products or accessories.

Sculptures and Cuts in Acrylic

- Manufacturing of lightweight, original pieces with geometric or abstract shapes.

- Execution of art exhibitions and decorative elements featuring high transparency and brilliance.

Glass and Metals

- From steel to aluminum, ideal for achieving durable, aesthetically pleasing cuts and engravings.

- Customization of pieces with names, dates, or intricate patterns.

Laser Cleaning

An Effective and Sustainable Solution.

Laser cleaning stands out as an innovative and environmentally friendly alternative for removing contaminants, oxides, or coatings from various surfaces. This process uses high-energy pulses to vaporize and dislodge impurities without compromising the integrity of the base material. Owing to its non-abrasive and chemical-free nature, it minimizes toxic waste and reduces wear on components, thereby extending their lifespan and enhancing production efficiency.

This technology is especially valuable in industries such as automotive, aerospace, and electronic component manufacturing, where maintaining surface purity is critical to product performance and reliability. With laser cleaning, you benefit from a rapid and secure process that translates into lower maintenance costs and stronger environmental protection.

Surface Preparation Before Welding

Removal of oxides, grease, and other contaminants to ensure a solid and reliable bond.

Reduction in the need for solvents and chemicals, thereby minimizing environmental impact.

Automotive Component Restoration

Cleaning of engine parts (blocks, cylinder heads, connecting rods) to eliminate deposits and residues without damaging the metal.

Weld and Seam Treatment.

Removal of residues and discolorations after the welding process to achieve more aesthetically pleasing finishes.

Simplification of maintenance by eliminating the need for wire brushes or polishers that can erode the component.

Aerospace Industry.

Cleaning of critical components (turbines, blades, propulsion systems) to optimize performance and safety.

Prevention of corrosion and extension of the operational life of parts subjected to high demands.

Electronics Manufacturing.

Removal of oxide layers and residues during the production of printed circuit boards (PCBs).

Enhancement of the reliability of joints and electrical contacts, thereby avoiding premature failures.

Art and Historical Heritage Restoration.

Removal of dirt, varnishes, and surface deposits from sculptures, facades, or antique carvings. P

Protection of delicate materials, such as stone or intricately worked metal, thanks to the precision of laser technology.

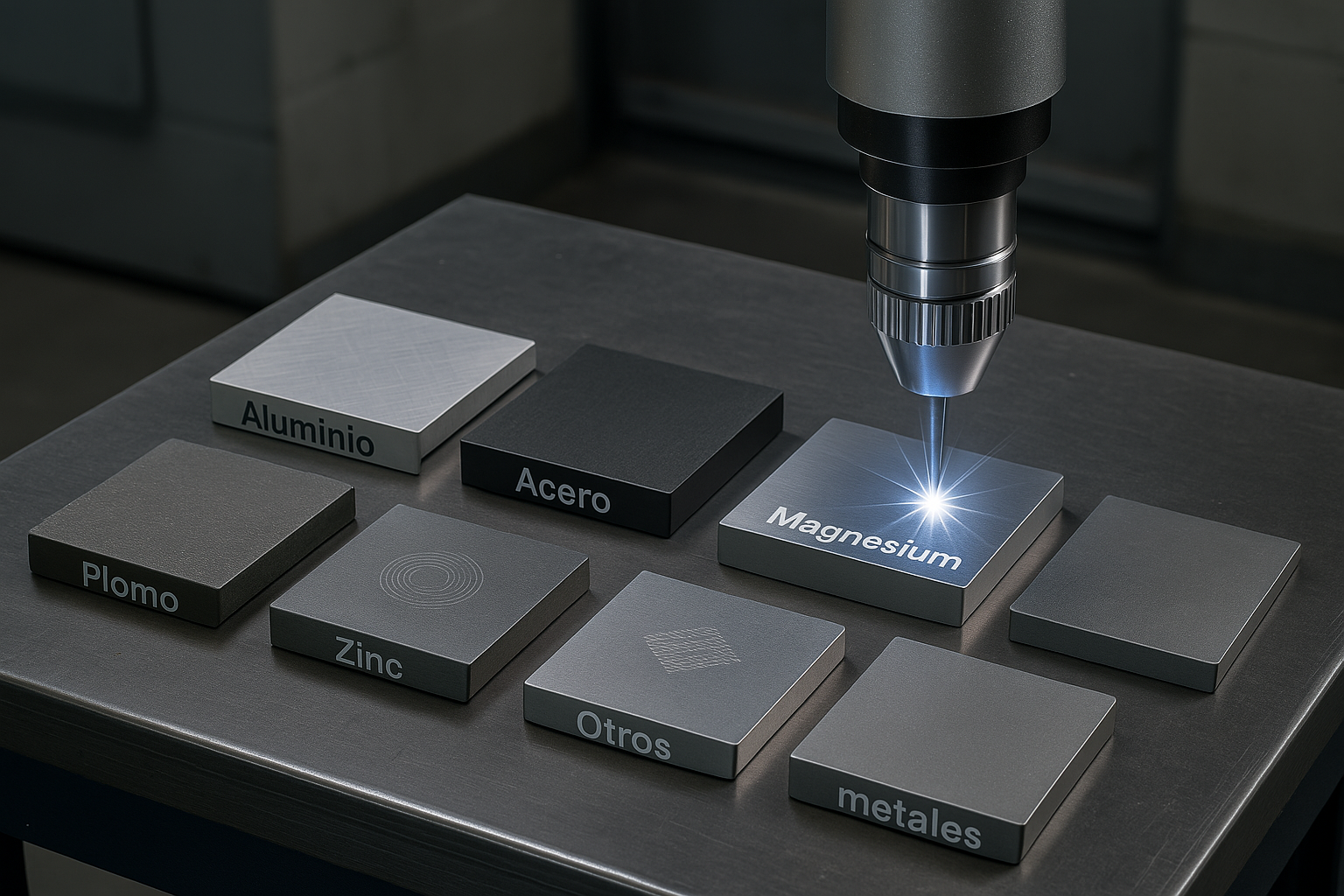

Materials compatible with laser marking

Laser marking is an advanced technology that uses a concentrated beam of light to alter the surface of various materials without physical contact. This process enables the creation of precise, permanent, and high-quality marks, making it ideal for product identification, customization, and traceability. The versatility of laser marking allows its application on both metallic and non-metallic materials, adapting to the needs of a wide range of industrial and creative sectors

Metallic Materials

- Aluminum

- Steel

- Anodized Aluminum

- Magnesium

- Lead

- Zinc

- Other Metals

Non-Metallic Materials

- PVC

- Plastic Polyethylene

- Stone and Brick

- Fabric

- Glass