Advantages of laser cleaning

Laser cleaning will become the preferred cleaning method in the future

Mechanical cleaning

• Damaged surface

• High-labor intensity

• Bad consistency

Ultrasonic cleaning

• Unstable quality

• Consumable

• Only suitable for cleaning attached particles

Chemical cleaning

• High consumable costs

Technology Advantages

• Quality consistency: Uniform and consistent over the lifetime of the laser

• Intelligent: easy to detect and control, process intelligence

• No damage: only surface contaminants are removed

• Easy operation: Automatic, handheld and online Technology Advantages Social & Economic Advantages

• Environmental protection: no chemical reagents, no noise

• Maintenance-free: no wearing parts

• Low operating costs: no consumables, less electricity

• Improve the working environment and greatly reduce manpower: solve the difficulty employing workers

Principle of Laser Cleaning

The absorption of the large energy forms a rapidly expanding plasma (a highly ionized unstable gas) that generates a shock wave.

The shock wave causes the pollutants to evaporate or peel off instantaneously.

With correct laser parameters and optimal wavelength, the base material will not be damaged or melted.

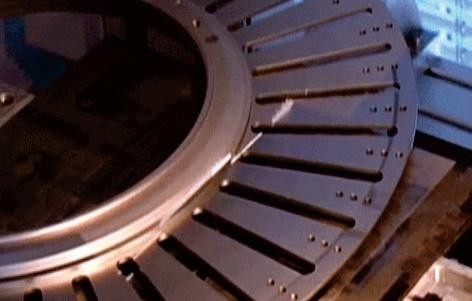

Laser Cleaning Application & Solution

Car surrounding/ship/rail transit

Rubber mold/environmental protection

industry, etc

Applications

• Metal Surface Rust Removal

• Surface paint removal

• Surface oil, stain, dirt cleaning

• Surface plating and coating

English

English  Español

Español